Pack Aircraft - Although still in the test phases, Skyflash has been designed to have an eventual cruising speed of 68k, with a range of 54nm and a maximum height of 11,800ft. Although it is not fully clear how it will land safely, it is fitted with a parachute just in case.

All these temperature and speed values above apply when the cooling pack is operating at the maximum cooling capability usually in hot and humid whether conditions on the ground. When the cooling demand is lower than the maximum (in flight), or when there is ice built up in the condenser or the exit of the turbine, some air is bypassing the system of the heat exchangers and the air cycle machine through a valve called ”Temperature Control Valve”. The hot bleed air melts the ice and frees the exit of the system, and at the same time the air passing through the heat exchangers and the air cycle machine is less,the speed decreases and the cooling pack delivers hotter air to the Air Conditioning System.

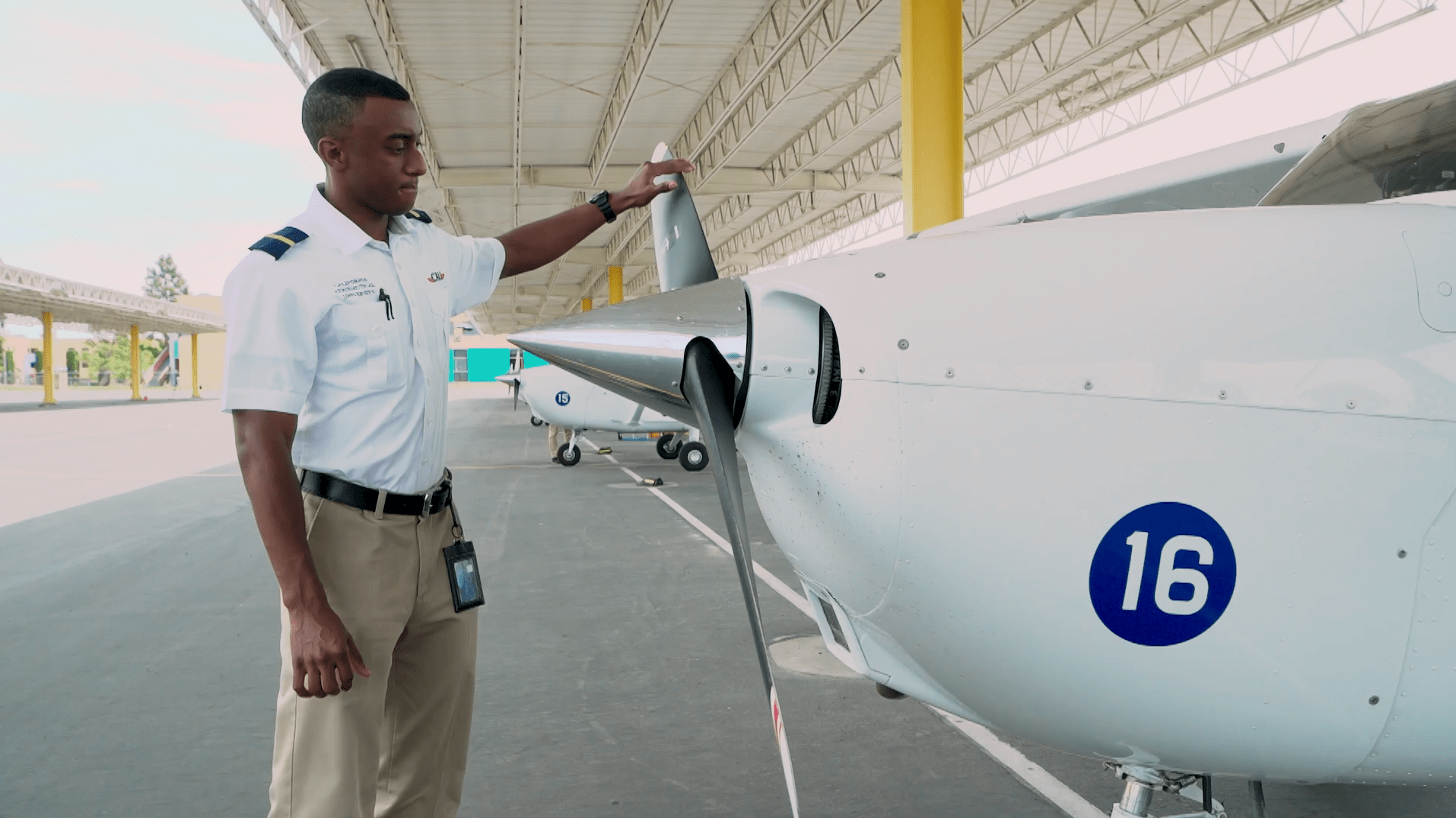

Pack Aircraft

Last generation Airplane Air Conditioning System Cooling Pack consists ofa Flow Control Valve, Primary and Secondary Heat Exchangers, Air Cycle Machine, Primary and Secondary Temperature Control Valve, Re heater, Condenser, Ozone Converter, a Water Separation System, Check Valves, and many sensors.

What Is A Hazardous Material?

Secure .gov websites use HTTPS A lock ( LockA locked padlock ) or https:// means you’ve safely connected to the .gov website. Share sensitive information only on official, secure websites.

From lithium batteries to aerosol whipped cream, many items used every day at home or work are regulated as hazardous materials (a.k.a. "hazmat" and "dangerous goods"). These products may seem harmless; however, when transported by air they can be very dangerous. Vibrations, static electricity, and temperature and pressure variations can cause items to leak, generate toxic fumes, start a fire, or even explode. Hazardous materials include, but are not limited to: explosives, gases, flammable liquids and solids, oxidizers, toxic and infectious materials, radioactive materials, corrosives, and many other items that can endanger the traveling public when not handled correctly. The good news is that many of the hazardous materials we can't live without are allowed in our baggage, but only if we follow the rules.

The Jet Pack H202 is made by a company founded by Troy Widgery, Jet Pack International (Jet PI), based in the US. It is a personal jetpack powered by hydrogen peroxide (H2O2), with flight capabilities having been demonstrated at various events by Jet PI.

Troy Hartman is developing a jetpack powered by two turbojet motors. Final testing was successfully concluded in 2011. The device is deployed in combination with a parafoil, working similarly to a parasail that isn’t being towed.

Jet Pack H

The compressor section compresses the air and increases the pressure and temperature. The temperature rise of the air passing the compressor section is about 30 to 40º C. This high pressure and temperature air goes through the Secondary Heat Exchanger, which is similar to the Primary Heat Exchanger Plate and Fin type made of aluminum, to remove the heat added by the compressor. The temperature drop of the air passing the secondary heat exchanger is about 60 to 70º C.

Basic Operation : Pressurized and hot air coming from the airplane Bleed System enters the Primary Heat Exchanger where it’s temperature is reduced, then enters the compressor section of the Air Cycle Machine where it’s temperature and pressure is raised again, then the air enters the Secondary Heat Exchanger reducing again it’s temperature, and finally it enters the Turbine section of the Air Cycle Machine expanding and releasing it’s energy to rotate the Turbine and the Compressor wheels being on the same shaft, with the temperature dropping down to 0 degree Celsius or below. At this temperature the moisture is condensed and is removed by a Water Separator.

The compact dimensions allow the jetpack to vertically take-off and land (VTOL), and operate in confined spaces that other aircraft simply cannot reach. The Martin Jetpack uses fly-by-wire technology, and a ballistic parachute system for recovery, making it one of the safest jetpacks available.

The Martin Jetpack was initially conceptualised and developed in 1981 by Glenn Martin in Dunedin, New Zealand, resulting in the establishment of the Martin Aircraft Company in 1998. The 200kg jetpack is powered by a V4 two-stroke engine, burning automotive gasoline. The aircraft will have more than 30 minutes flight length, at a maximum speed of 74km/h, achieving a top altitude of 1,000m (3,000ft).

Troy Hartman Jetpack

When in cruising altitude the need for cooling is at a minimum because of the very low ambient temperature at that flight level, the most of the bleed air is passing just through the heat exchangers being cooled from the ram air. In this case the speed of the air cycle machine is the minimum or in the last generation systems it is completely stopped.

Damaged or recalled batteries and battery-powered devices, which are likely to create sparks or generate a dangerous evolution of heat, must not be carried aboard an aircraft (e.g. carry-on or checked baggage) unless the damaged or recalled battery has been removed or otherwise made safe. The airline may offer further public guidance on transporting individual recalled products.

The Rocket Belt is powered by a single rocket engine, burning rocket-grade hydrogen peroxide fuel and offers a maximum flight time of up to 30 seconds. It is equipped with heads-up display electronic control timer, developed by TAM.

Troy began working on the Jet Wing in 2008, which resulted in the development of a personal jet-backpack. The testing of this jetpack-on-skis was conducted in January 2011, which proved the flight capabilities. Troy successfully made his jet-backpack to fly with a ‘speed wing’ in August 2012, as part of the jet-wing design testing.

Damaged Or Recalled Batteries And Battery-Powered Devices

COVID-19 test kits containing diagnostic samples (e.g., nasal swabs and vials of sputum) are not allowed in carry-on baggage. These samples must be properly packaged, handled, and identified as a UN3373 Category B Infectious Substance (PDF) during transportation. Passengers should check with their carrier before packing COVID-19 test kits containing diagnostic samples in checked baggage or shipping as cargo. Individual carriers and international requirements may be more restrictive than domestic regulations.

Security Screening Questions: The Transportation Security Administration also has rules on "prohibited items" that pose a security threat. Though they sometimes overlap, the TSA security rules are separate from the FAA dangerous goods safety rules; go to the TSA Prohibited Items web page.

The bleed air enters the Cooling Pack through an Ozone Converter which transforms ozone contained in bleed air into Oxygen by Catalytic Effect, then passes throughFlow Control Valve which regulates the flow according to the Air Condition System and Cabin Pressurization System demands.

There have been many attempts to build a fully functioning jetpack, with mixed results. The concept is not without its risks, yet the sci-fi dream is slowly becoming a reality thanks to the sheer will of inventors. Aerospace-technology.com lists the world’s most innovative means of allowing people to fly.

Powerhouse Productions’ Rocketbelt

The Rocketbelt in was unveiled by Powerhouse Productions in July 1981, and owned and operated by Kinnie Gibson, popularly known as ‘The Rocketman’. The capabilities of the Rocketbelt have been demonstrated by the company in exclusive performances worldwide.

Skyflash is being developed by Fritz Unger and his group of friends from Germany all on a shoestring budget. Featuring rigid wings spanning approximately 3.4m (11ft) inspired by condors, it is powered by two turbo jet engines that run on diesel.

The maximum gross take-off weight of both variants is 340lb. The TP-R2G2 runs off standard high-test H2O2, and can burn it with JP4, JP5 or JP10 in dual-fuel mode. Dual-fuel propulsion provides a speed of 120km/h, and a range of 1,112m (3,650ft).

The dry air goes through the re heater to warm the air that goes to the turbine to increase the turbine efficiency. The inlet temperature of the turbine section of the air cycle machine is at a level of 20 to 10º C

Fritz Unger Cloudflash

The water extractor duct removes some moisture condensed after the air passed and cooled from the Secondary Heat Exchanger, using the centrifugal effect swirling the air through vanes to separate water particles from the air and sends the moisture to a water collector.

Rapid expansion and energy extraction across the turbine lowers the temperature of the air down to -10º C and rotates the turbine wheel together with the wheels of the compressor and the fan being on the same shaft to a speed of 40.000 to 50.000 rpm.

Oldham Engineering is a turnkey project management specialist, providing in-house services of design, coded fabrication (BSEN ISO 3834-2), medium-heavy (30t - 10m) precision, computer numerical control (CNC) machining and robot welding, as well as complex assembly and testing for bespoke projects and batch production.

The Cooling Pack, or Air Condition Pack, is an air cycle refrigeration system that uses the air passing through and into the airplane as the refrigerant. This is accomplished by a combined turbine and compressor machine, called Air Cycle Machine (A.C.M.), valves for temperature and flow control, and heat exchangers using outside air to dispense waste heat. The air condition pack provides essentially dry, sterile, and dust free conditioned air to the airplane cabin at the proper temperature, flow rate and pressure to satisfy pressurization and temperature control requirements.

Air Cycle Cooling Pack

Flow controlled bleed air then goes first to the Primary Heat Exchanger at an average pressure of 30 to 40 p.s.i.and temperature of 150º C, where ram air removes heat from the bleed air. The temperature drop of the air passing the primary heat exchanger is about 100º C.

Some of the items you pack in your baggage may be considered dangerous goods, also known as hazardous material. Most dangerous goods are forbidden in carry-on and checked baggage. There are a few exceptions for some personal items such as toiletries, medicines, and assistive devices. Check the chart below to see which common dangerous goods are allowed in checked and/or carry-on baggage and which are not. Remember, this is just a listing of common dangerous goods; if you don't see your item here it doesn't mean it's allowed in baggage. When in doubt, leave it out!

The advanced jetpack can carry a pilot weighing up to 81.6kg (180lb), and can fly at a maximum speed of 124km/h. Powered by hydrogen peroxide (H2O2), the Go Fast Jet Pack generates approximately 300lb of thrust, for 33 seconds of total flight. The fuel tank capacity of 20l (5.3gal), allows it to reach a distance of up to 762m (2,500ft).

The TAM Rocket Belt is produced by Tecnologia Aeroespacial Mexicana (TAM), based in Mexico. The jetpack is offered along with a training and support package, including test flights, as well as installation, maintenance, and round the clock technical support.

For A Safe Start Check The Chart

The jetpack can take-off with a pilot weighing up to 81.6kg (180lb). It has a maximum speed of 112.6km/h, is able to reach a distance of 402m and achieve a height of 36.5m. The flight time of the jetpack is 23 seconds.

The TP-R2G2M has flight duration of up to 45 seconds with a standard pilot weight of 72.5kg (160lb). The actual flight duration varies depending on fuel load, pilot weight, plus payload and variations in acceleration during flight. The TP-R2G2D offers maximum flight duration of 75 seconds while carrying a standard 72.5kg pilot and a 9kg payload.

TAM also offers a custom-built rocket belt according to users’ specifications. The TAM Rocket Belt is available in three different rocket engine and frame geometries, as well as three fuel tank size capacities, and five control valves and flow-rates.

Operation of the Cooling Pack : When the pack is operating on the ground, ram air is pulled across the heat exchangers by the impeller fan powered by the turbine section of the air cycle machine, or in older configurations by a turbofan where the fan is powered by a turbine rotated by high energy bleed air of the pneumatic system, or by powerful three phase alternating currentelectric blowers, while for the in flight operation the ram air is more than enough to cool the heat exchangers, and the operation of the fans stop in case they are electrically or bleed air powered, or they are bypassed by a check valve into the ram air duct in case they are powered by the turbine section of the air cycle machine.

Your Rocket Belt

aircraft pack system, msfs 2020 mega pack aircraft, air conditioning pack aircraft, aircraft hauling service, six pack aircraft, spacewalker airplane for sale, jet pack flying, airplane factory