Parts Of Aircraft - During the flight, the aeroplane with the nose mostly around it pushes the air in front of them so that it allows it to use minimum resistance and helps it to move forward. No did the nose can also be built beneath the wings but in a smaller

radiant. Some aircraft of composite materials began to appear in the late 1930s and '40s; normally these were plastic-impregnated wood materials, the most famous (and largest) example of which is the Duramold construction of the eight-engine Hughes flying boat. A few

Parts Of Aircraft

production aircraft also used the Duramold construction materials and methods. The use of composite materials opened up whole new methods of construction and enabled engineers to create less expensive, lighter, and stronger parts of more streamlined shapes than had previously been feasible with wood or metal. Like the computer, the use of composites has rapidly spread

Self-Tapping Screws

throughout the industry and will be developed even further in the future. Aircraft Rivets Sheet metal construction is very popular within our industry. A number of very high quality designs are available to build using sheet metal. Sheet metal construction of some sort is required on a large number of aircraft including restorations of antiques and classics a Rivets

role in this type of construction. Even the best built parts of an aircraft are only as good as what holds them together. Aircraft made of wood and fabric were difficult to maintain and subject to rapid deterioration when left out in the elements. This, plus the need for greater strength, led to the use of metal in aircraft. The first general use was in World War I,

when the Fokker aircraft company used welded steel tube fuselages, and the Junkers company made all-metal aircraft of dual tubing and aluminum covering. The elevator of her plane is the movable part of the aircraft; still, it helps to move the plane up and down. As the deal of the plane cannot move on its own, the elevator helps the deal move upward does interactively, helping the aeroplane

start when the pilot presses the button. This type screw is used for attaching removable parts and in parts where the screw can cut its own threads. Self tapping screws should not be used to replace standard screws, bolts, or rivets. They are made for non-structural purposes. They are available

Piano Hinge

with a round head, truss head, oval head, or flat head. They also have two different shank types: Type A, that is coarse threaded with a sharp point and Type B, that has a blunt point. Type A is used with sheet

metal and Type B in conjunction with Tinnerman nuts. Piano hinge? Yes, we do use piano hinge in building our aircraft. Piano hinge is used as a simple hinge for inspection doors, cowlings, for a quick disconnect fastener, etc.. Two types of piano hinge are available. The first is MS20257

that is made of aluminum and has bent hinge loops. Two half-hinges are held together with a hinge pin. The other type is MS20001 that is an extruded hinge made of stronger material than the MS20257. This hinge has a pin but cannot be pulled

apart. This is the type recommended for structural use. The coincident arrival of the new technology in computers and composite materials influenced commercial air transportation, where aircraft larger than the Airbus A380 and faster than the Concorde are not only possible but inevitable. In the field of business aircraft, the new technologies in have a result

Aircraft Screws

host of executive aircraft with the most modern characteristics. These include the uniquely configured Beech Starship, which is made almost entirely of composite materials, and the Piaggio Avanti, which also has a radical configuration and employs primarily metal construction components but includes a

material. Commercial air transports are using composite materials in increasing amounts and may ultimately follow the pattern of the military services, where large aircraft like the Northrop B-2 are made almost entirely of advanced composite materials.

Screws are probably the most common fastener found on a light airplane. Most are made of a lower strength material than bolts. However, structural screws are made of the same material that you will find in a bolt. Three types of screws are usually found on

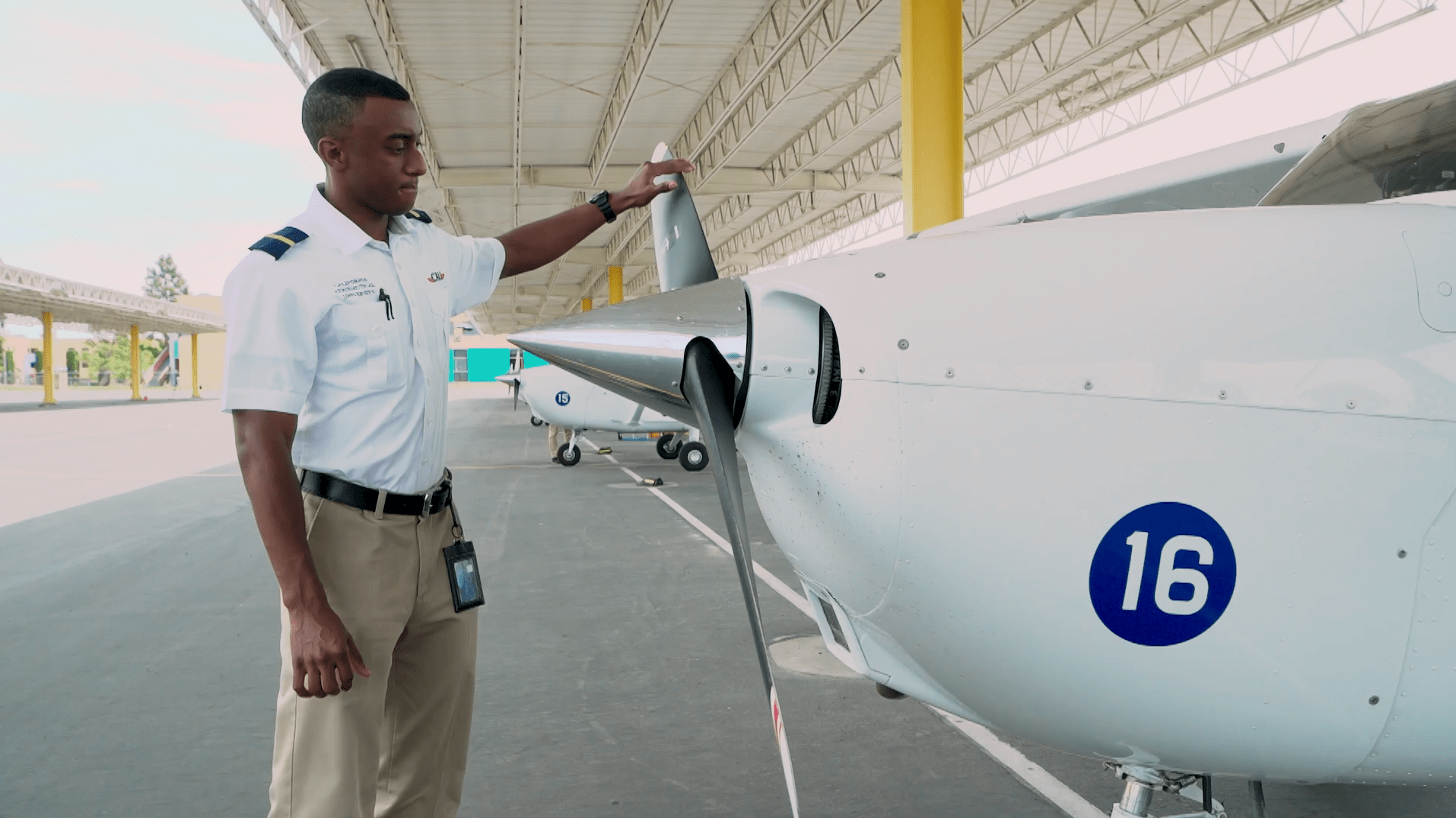

an aircraft: machine screws, structural screws, and self-tapping screws. Drive screws are also used but they are actually driven like a nail rather than being threaded like a screw. The propeller of an engine works by pulling the air behind itself fraction to convert the rotational energy into force. The force once created pushes the aeroplane forward; the more that is pulled behind the profiler, the more thrust is applied forward so that the engine can

Landing Gear

start working and the aircraft can take off smoothly. Three other areas of civil aviation have benefited enormously from these advances in technology. The first of these are vertical-takeoff-and-landing aircraft, including helicopters. The second are sailplanes, which have reached new levels in structural and aerodynamic.

are the wide variety of hang gliders and ultralight aircraft, as well as the smaller but more sophisticated aircraft that depend on human or solar power. Each of these has been vastly improved by contemporary advances in design and construction, and each holds great promise for the

future. During the late 1940s, interest developed in fiberglass materials, essentially fabrics made up of glass fibers. By the 1960s, enough materials and techniques had been developed to make more extensive use possible. The term “composite” for this method of construction use the indicate

of different materials that provide strengths, light weight, or other functional benefits when used in combination that they cannot provide when used separately. They usually consist of a fiber-reinforced resin matrix. The resin can be a vinyl ester, epoxy, or polyester,

Use Of Composite Materials

While the reinforcement might be any one of a variety of fibers, ranging from glass through carbon, boron, and a number of proprietary types. The excellent work of a landing gear of the year craft is to give support when parked, taking off and landing. Every aeroplane doesn't need to have landing gear; it can also have operators of skis to help it at water or snow.

Has a shock absorber, wheel, brake and undercarriage that help to observe the lending impact of energy and load transfer. Machine screws are for general purposes and they are available in low carbon steel, aluminum, stainless, and brass. They are manufactured with a roundhead, washer head, pan head, truss head or countersunk head. They can be fine thread or coarse thread.

The designations used in screws are many and varied. AN526 is a good example of a common machine screw. It is a cadmium plated truss head screw. An AN526C ("C" designates corrosion resistant) would be a stainless screw. A MS24693 is a

100 degree flat head screw. The list goes on and on. The use of composite materials, similarly assisted in both design and application by the use of computers, has grown from the occasional application for a nonstructural part (e.g., a baggage compartment door) to the construction of complete airframes. These materials have the additional advantage

Structural Screws

in military technology of having a low observable (stealth) quality to radar. The engine of air plains is located just beneath the wings that provide methods to overcome what the aeroplane faces when they take off from land by pushing away the air. They typically run on Aviation gasoline to allow a higher compression rate during flight.

Structural screws are made of steel alloy and are heat treated. They may be used as structural bolts. They have a grip length similar to a bolt and they will have the same strength as a bolt of a similar size. They too are available with different

types of heads. Structural screws will not be threaded over their entire length versus a non-structural screw. See Figure 7. Aluminum parts may be riveted, bolted, or welded together. Riveting is the most common method used. Rivets are used on sport aviation aircraft as well as metal airplanes as large as a Boeing 747. We are talking thousands of rivets on a typical airplane

Rivets are light in weight and cheap in price. Rivets are not only used to hold aluminum sheets together, but they are also used in securing fittings, nut plates, spars and ribs, etc.. Simply defined, a rivet is a bolt without a

Blind Rivets

nut. More precisely, it is a small metal pin that when properly installed provides a very effective and strong bond. Volumes of material can be written on the subject of aircraft hardware and its proper use. I am going to continue by elaborating only on the highlights of aircraft hardware that apply to the sport aviation industry. This and subsequent articles will present more of what I think

you need to know to build your airplane or to complete a restoration. Hopefully, the items discussed will be of practical value to you as you go through the building process. This month, I will discuss in detail aircraft rivets along with more general information regarding

screws, turnlock fasteners, O-rings, piano hinge, etc. Subsequent articles in this series will focus on control cables, fluid lines, and electrical connections. A significant amount of time in the building process will be used selecting and installing hardware. The more familiar you are with the proper selection and installation of hardware means less

time consumed in the building process. Moreover, you will be assured that the assembly of your project is both safe and of the highest quality. Two cheaper versions of Cherry rivets are available. These are called Cherry "N" and Cherry "Q". Cherry "N" rivets are non-structural. Cherry "Q" rivets have limited structural use. They do provide a high shear strength.

Basics Of Rivet Installation

A number of kit manufacturers use the Cherry "Q" type rivet in the construction of their aircraft. A propeller is an aerodynamic device that converts rotational energy into force. This force propels the airplane forward. This creates thrust that is perpendicular to its plane of rotation. Propellers have two or more blades. Propeller blades are spaced evenly around the hub.

available in either fixed pitch or variable pitch configurations. An aircraft engine, or aero engine, is the power source for a plane. Most are either piston engines or gas turbines. Some drones, or unmanned aerial vehicles (UAV), have used electric motors. There are many manufacturers and models of engines.

Each is designed for specific aircraft, whether large or small. Manufacturers recommend an engine overhaul at specified times after an engine has flown a certain number of hours. The winglet is a vertical extension of the wingtips, designed in a very small structure and reduces the drag by going against the airflow. The main work of the winglets is doing trees the operation of the plane by reducing the drag from the tip of the wings

.In addition, the air pressure monitors the functioning of the winglet does cutting down the fuel consumption that can value from 3 to 7%. As speeds advanced, so did structural requirements, and designers analyzed individual aircraft parts for both strength and wind resistance. Bracing wires were given a streamlined shape, and some manufacturers began to make laminated wood fuselages of monokincoques construc

Instrument Panel

Greater strength, better streamlining, and lighter weight. The 1912 record-setting French Deperdussin racers, the German Albatros fighters of World War I, and the later American Lockheed Vega were among the aircraft that used this type of construction.

Rivnuts are another type of blind rivet. They are used to install access covers, wing fairing, floors, etc.. Rivnuts are threaded to accept screws or bolts. They are used very much like a nutplate. Basically, a rivnut is a tubular aluminum

rivet with internal threads. See Figure 5. A special tool is required for installation. The tool expands the shank tightly against the material being fastened. Rivnuts are available with a flat head or a countersunk head.

In the beginning, what we knew was only the land and waterways of transportation, but with time a machine is capable of flying in the air, which is popularly called in aircraft; aircraft includes helicopters, aeroplanes, hot air balloons, anything which flies in

Turnlock Fasteners

the air. Rivets are commonly sold in ¼ pound bags. Obviously, the number of rivets in a bag will vary depending upon the size of the rivet. As an example, using our MS20470AD4-8 rivet, approximately 300-400 would be found in a ¼ pound

bag. Supply catalogs should provide you with this information. These rivets are fairly inexpensive—normally $4-$5 per ¼ pound bag. The fin is a part of the empennage and is mostly found in the top rear of the fuselage. The vertical dealer of the aircraft has a vertical stabilizer fin which is the same as the work of a tail. It works to stop the vehicle's unwanted rolling

and help it stabilize while landing taking off parking, or doing other movement activities. Camloc fasteners consist of a stud assembly, grommet, and a receptacle. The receptacle is usually riveted to the structure of the aircraft. Once again, ¼ turn locks the fastener. Three types of Camlocs are available: 2600, 2700, and 4002. The

4002 series is stronger than the 2600 and 2700 series. All are made of steel and rated to 450 degrees F. Once again, special tools are required for installation. The size and type of rivet to use should be included in your plans or assembly manual. Once again, do not substitute. Use what the designer recommends. Also, do not try to save money on tools. A good rivet gun is a valuable tool

Elastic Grommets

—get a high quality rivet gun. Use a rivet squeezer whenever possible. Squeezing a rivet is much easier and more effective. A few rules of thumb concerning rivet installation: As an aside, you may have heard the term "icebox rivet." That type rivet is usually manufactured out of 2017 or 2024 aluminum. They are announced and used for very high strength purposes. They must be kept cold (refrigerated) until they are

used. They must be driven within a short period of time after removal from the refrigerator. This type rivet is more common in larger aircraft and is rarely used within our industry. One other type rivet you may encounter is a 5056 rivet that is used for

Magnesium alloy structures. Complementing and enhancing the results of the use of computers in design is the pervasive use of computers on board the aircraft itself. Computers are used to test and calibrate the aircraft's equipment, so that, both before and during flight, potential problems can be anticipated and

corrected. Whereas the first autopilots were devices that simply maintained an aircraft in straight and level flight, modern computers permit an autopilot system to guide an aircraft from takeoff to landing, incorporating continuous adjustment for wind and weather conditions and ensuring that fu

Early Technology

In the most advanced instances, the role of the pilot has been changed from that of an individual who continuously controlled the aircraft in every phase of flight to a systems manager who oversees and directs the human and mechanical resources in the cockpit.

The hold of any aircraft is the place where the cargo is given. To be precise, it is where the luggage is taken during checking and is then transferred to the bank dropout counter from where you can pick up your luggage. It is not a regular

part of the thing, but all the plain languages are landed in the drop counter, so it is a shift of weight considered to be a part of a particular aircraft.

parts of an airplane, different parts of a plane, main parts of an airplane, parts of plane, basic parts of an aircraft, used aircraft parts for sale, parts of aircraft wing, aircraft parts for sale